NCU Inspection of Wind Turbine Blade Carbon Fiber Reinforced Polymers (CFRPs)

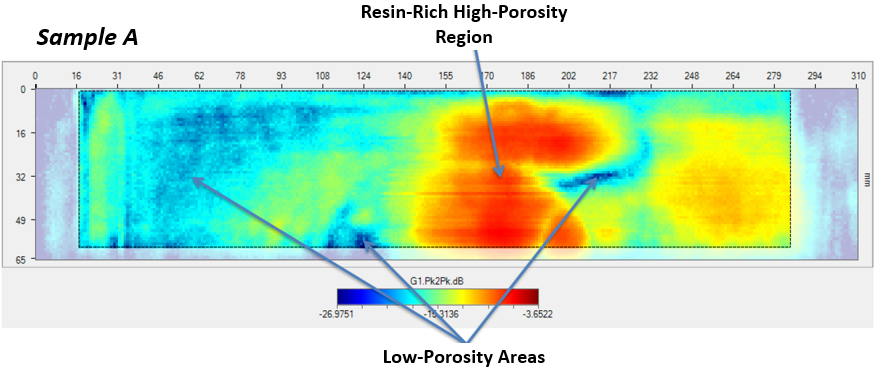

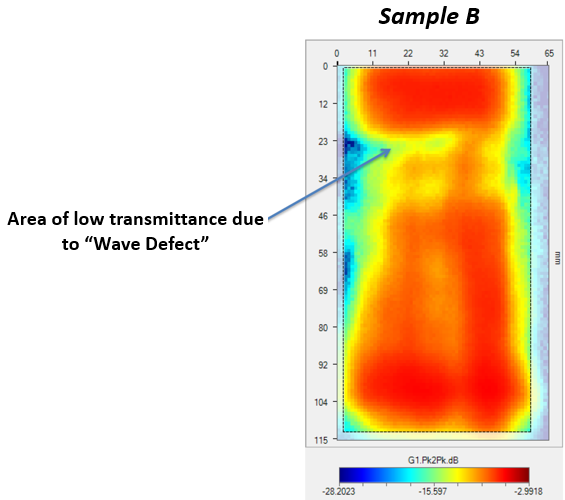

Ultran inspected carbon fiber reinforced polymer wind turbine blade components using non-contact ultrasound to measure porosity variation and other defects.

The results demonstrate a clear ability to distinguish between porous and resin-rich areas using non-contact ultrasound.

The application was further developed for Tecsis Corporation, a major manufacturer of wind turbine blades, for the purpose of creating a robust method of in-process inspection. The in-process inspection method included a multi-channel system for high throughput analysis.

Wind Turbine Blade CFRP Samples Provided by Tecsis Corporation