Non-Contact Inspection of Composite Helmets for Military Use

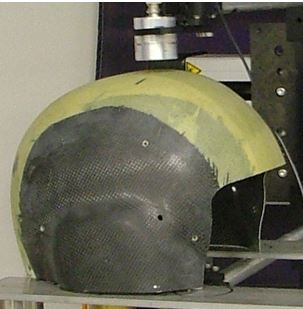

Ultran has applied its non-contact ultrasound technology for the purpose of detecting delamination defects in composite military grade armor, such as helmets for soldiers.

As composite materials are exposed to impact, delamination can become prevalent, which decreases the strength and protectiveness of the helmet.

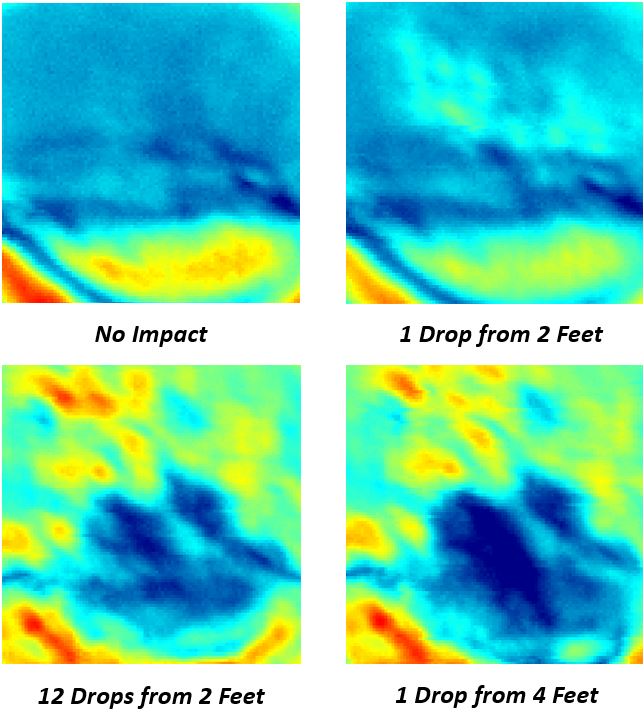

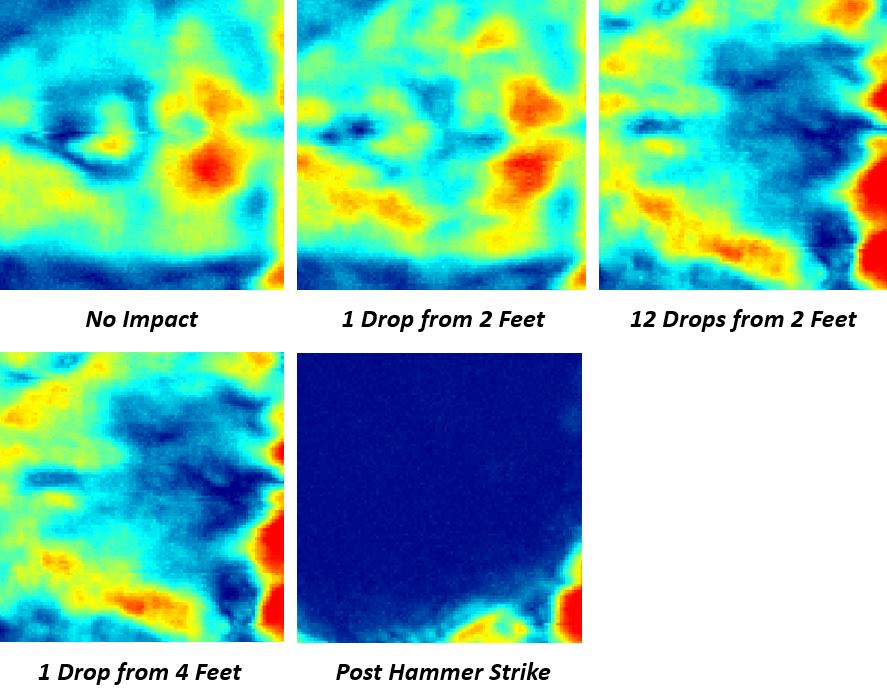

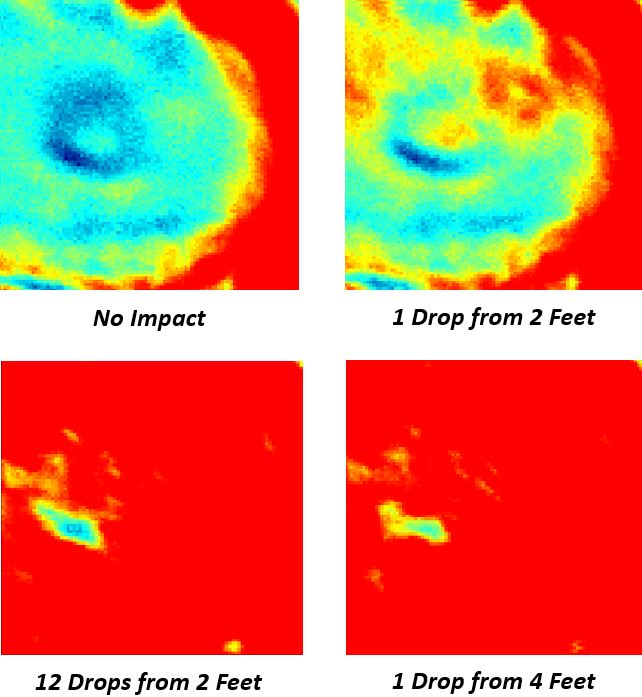

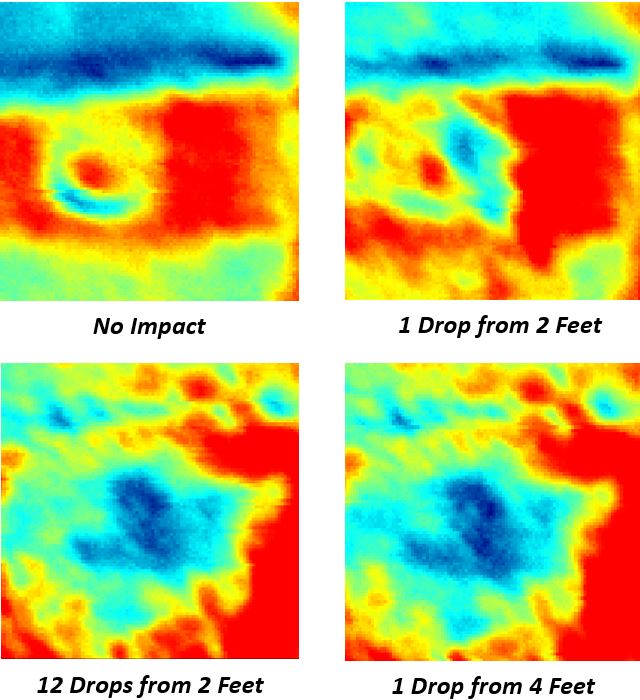

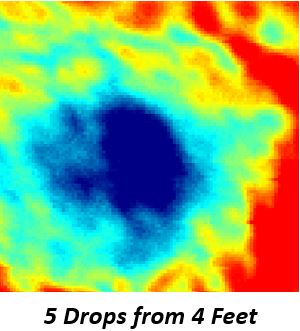

As shown below, non-contact ultrasound can measure the degree of damage incurred by the helmet during a series of drop tests.

With each drop test conducted, the delamination in the helmet increases and the transmissivity of non-contact ultrasound changes.

- On the front side of the helmet, results show that transmissivity decreases with damage.

- On the back side of the helmet, results show that transmissivity increases with damage.

Non-contact ultrasound is an effective and non-destructive method of inspecting composite helmets during maintenance as well as during production.

Composite Helmets for Military

Helmet Front Center – Sample 1

Helmet Rear Side – Sample 1

Helmet Front Side – Sample 2

Helmet Rear Side – Sample 2