Inspection of Delamination Between Bonded Metal Substrates

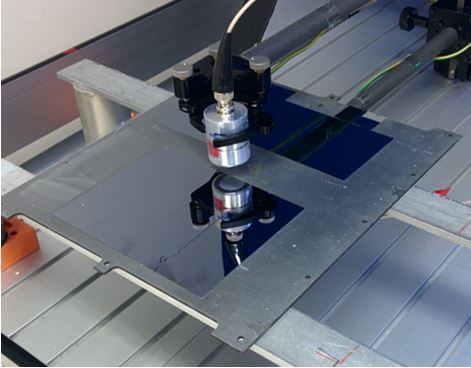

Ultran and its customers have applied its non-contact ultrasound products for the purpose of detecting the bond quality between bonded metal substrates.

A large number of samples for different purposes have been analyzed, showing a distinction between well-bonded areas and areas of low bond strength or delamination.

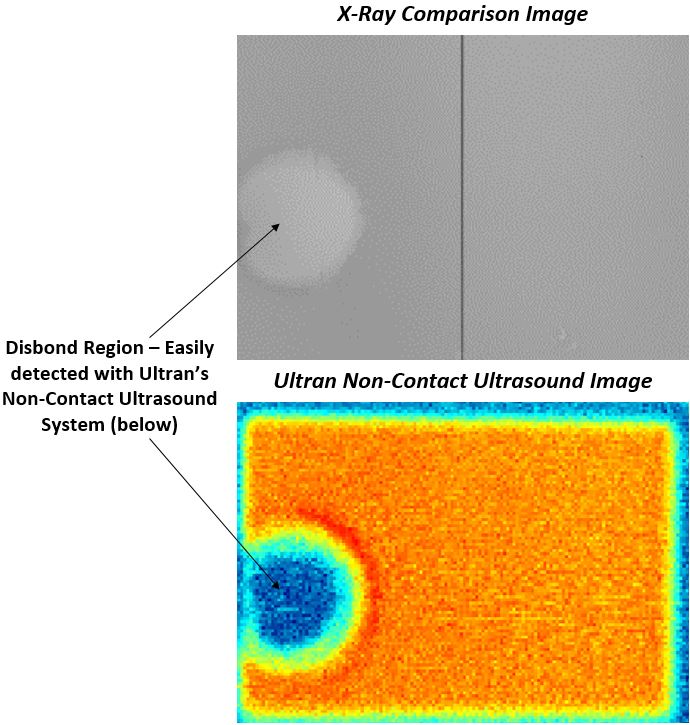

For this example, the objective is to detect delamination between the Mo plate and Silicon wafer. The non-contact ultrasound results are compared with an image created from X-ray detection.

Sample specifications:

- Molybdenum (Mo) plate with thickness of approximately 1-2 mm

- Silicon wafer bonded to Mo with thickness of approximately 500-750 µm

- Acrylic adhesive film between the two substrates with thickness of approximately 50 µm

While X-ray requires expensive equipment, environmental encapsulation, and approximately 10-30 minutes to produce a high-resolution image, non-contact ultrasound is capable of imaging this part in approximately 30 seconds in ambient conditions.

Molybdenum-Silicon Bonded Composite Structure