Inspection of Conveyor Belt Rubber Products

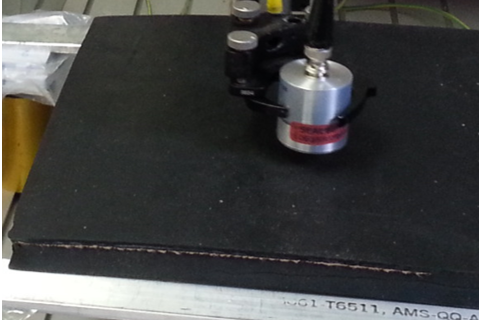

Ultran has analyzed industrial rubber and developed a robust process for inspection of conveyor belts for mining applications. Applications include defect detection (delamination and foreign objects), porosity and density measurement, and more.

- Application developed for Veyance Corporation

- Method used to detect defects validated for inline field inspection of mining conveyors

- Analysis conducted at various frequencies, using focused and planar transducers

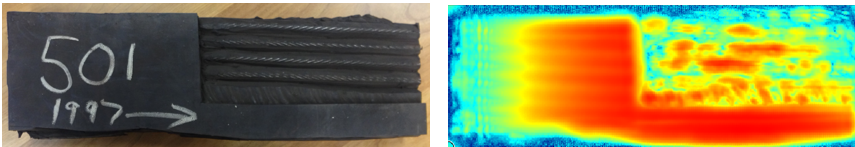

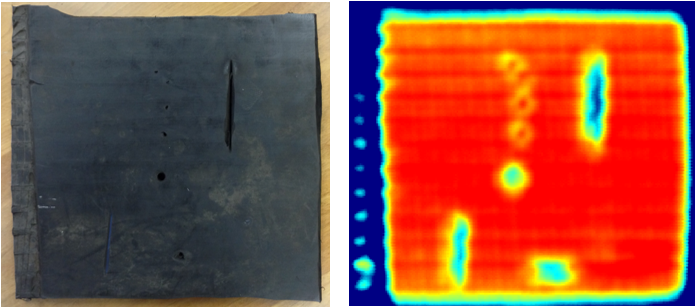

Mining Conveyor Belt Material with Embedded Defects

Provided by Veyance Corporation

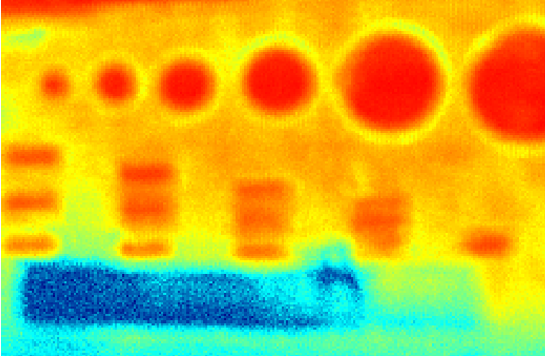

Various Internal Defects Detected, including voids and foreign objects

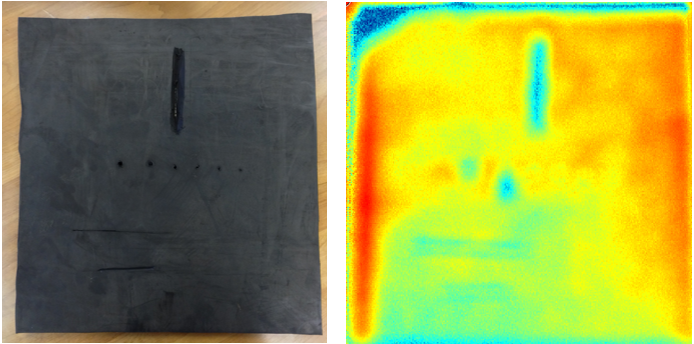

Additional Conveyor Samples with Various Defects and Properties

Sample A

Sample B

Sample C